Remain Ahead of Wear and Tear: Necessary Upkeep Tips for Undercarriage Parts

Remain Ahead of Wear and Tear: Necessary Upkeep Tips for Undercarriage Parts

Blog Article

Make The Most Of Efficiency With Sturdy Undercarriage Parts

In the world of hefty equipment and devices, the function of undercarriage parts is vital in ensuring ideal efficiency and durability. The effectiveness and efficiency of these elements can substantially influence the overall operation of machinery, making the selection of resilient undercarriage parts a vital decision for drivers and managers alike. By exploring the complex relationship in between resilience and efficiency in undercarriage parts, a much deeper understanding of the subject emerges, shedding light on the pivotal factors that drive operational success. As we navigate via the complexities of undercarriage upkeep, element, and durability selection, a detailed expedition waits for to reveal the crucial strategies for attaining peak efficiency in sturdy applications.

Benefits of Utilizing Sturdy Undercarriage Components

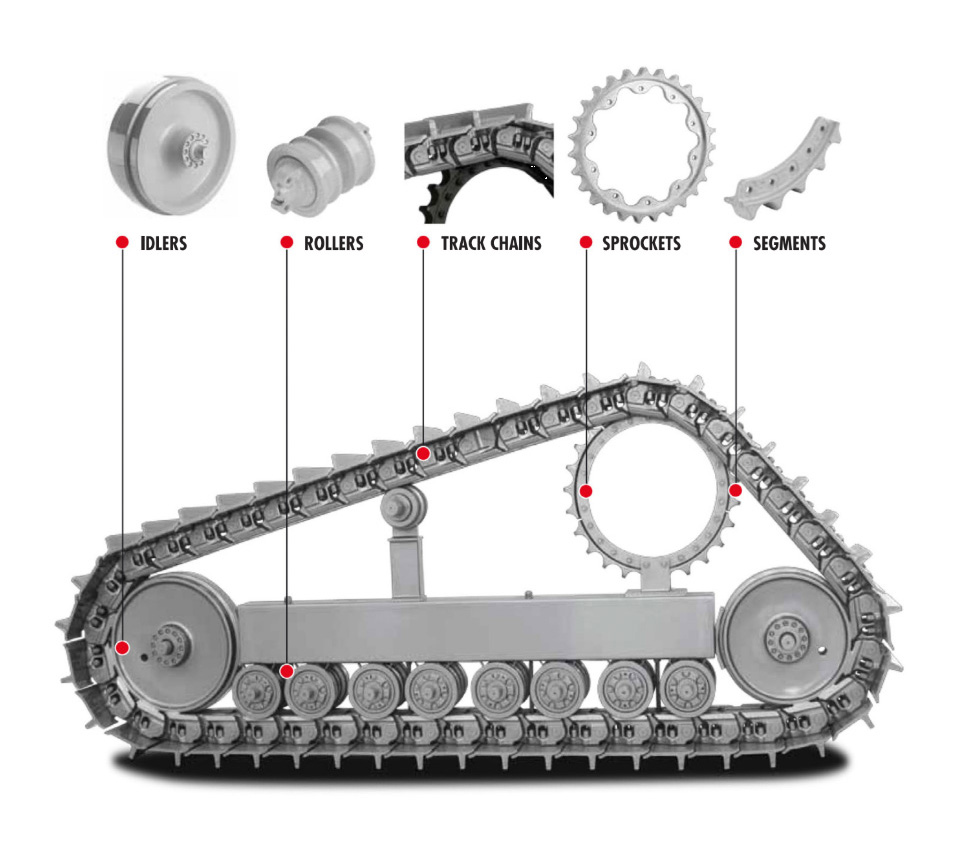

Using sturdy undercarriage components not just boosts the durability of hefty machinery but likewise lessens upkeep prices significantly. By purchasing high-quality undercarriage components, such as tracks, idlers, gears, and rollers, equipment drivers can experience boosted uptime and boosted general efficiency.

Additionally, the durability of hefty equipment is directly connected to the high quality of its undercarriage parts. Resilient parts can hold up against the roughness of requiring applications, guaranteeing that the tools stays functional for extended periods. Consequently, drivers can prevent pricey downtime and upkeep expenditures, eventually optimizing the roi for their machinery.

Elements Impacting Undercarriage Sturdiness

The toughness of undercarriage parts in hefty equipment is influenced by various critical factors that straight impact efficiency and longevity. Premium products, such as hard steel, are vital for withstanding the severe conditions and hefty lots that undercarriage components are subjected to - undercarriage parts.

Furthermore, environmental elements can have a considerable effect on the long life of undercarriage components. Exposure to unpleasant materials, severe temperatures, and harsh working conditions can increase wear and tear on undercarriage parts. For that reason, picking undercarriage parts that are especially developed to endure these ecological difficulties is crucial for making sure sturdiness.

Furthermore, the design and engineering of undercarriage components have a straight influence on their durability. Parts that are created to disperse loads uniformly, decrease rubbing, and decrease tension concentrations are more probable to have a much longer life-span - undercarriage parts. By taking into consideration these crucial elements, equipment drivers can take full advantage of the sturdiness and efficiency of their undercarriage elements

Maintenance Tips for Lengthening Undercarriage Life

Implementing normal maintenance regimens is crucial for extending the life expectancy of undercarriage components in heavy equipment. To lengthen the undercarriage life, it is vital to frequently check for damage. Frequently examine for loosened or missing screws, harmed rollers, or misaligned tracks, as these issues can escalate and create further damage otherwise attended to quickly. Furthermore, guarantee that the undercarriage is correctly lubed according to manufacturer guidelines to decrease rubbing and prevent early wear.

One more important maintenance idea is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can increase wear and deterioration, causing pricey repair services. Washing the undercarriage after procedure in rough conditions is suggested to avoid these issues.

Finally, tracking and recording maintenance activities can aid in developing an aggressive upkeep timetable. Maintaining comprehensive records of repair work, substitutes, and examinations can supply beneficial insights into the undercarriage's condition and performance gradually, assisting in forecasting and preventing potential failures. By complying with site these upkeep ideas faithfully, drivers can considerably enhance the toughness and efficiency of undercarriage components in hefty machinery.

Selecting the Right Undercarriage Parts

Picking proper undercarriage components is crucial for maximizing the performance and durability of hefty machinery. When it comes to choosing the ideal undercarriage components, there are numerous elements to take into consideration.

Choosing for trustworthy brands known for creating long lasting and high-performance undercarriage components can considerably affect the general effectiveness and durability of the equipment. By meticulously selecting the best undercarriage parts, tools owners can enhance productivity, minimize downtime, and prolong the life expectancy of their heavy machinery.

Study: Improved Performance With Sturdy Parts

Integrating sturdy undercarriage parts has shown substantial enhancements in machinery efficiency. One case research study included a building and construction company that upgraded its excavator's undercarriage parts to more resilient choices.

In an additional instance, a mining operation replaced the undercarriage components of its excavator with high-quality, resilient options. This button brought about a remarkable enhancement in the bulldozer's ability to move and total Learn More Here efficiency. The equipment could navigate difficult terrains a lot more successfully, bring about boosted operational efficiency and decreased fuel usage.

Furthermore, a logging business purchased long lasting undercarriage components for its forestry devices. The updated parts showed long term life-span and raised resistance to abrasion from harsh surface. Subsequently, the firm experienced lowered upkeep expenses and enhanced devices uptime, eventually increasing its profits. These instance researches underscore the substantial advantages of making use of long lasting undercarriage parts in enhancing machinery efficiency and durability.

Final Thought

In final thought, utilizing resilient undercarriage components can considerably boost performance and durability of hefty equipment. Case research studies have actually shown that investing in long lasting undercarriage components can lead to improved general efficiency and performance in various industries.

The effectiveness and performance of these parts can considerably influence the general procedure of equipment, making the selection of durable undercarriage parts a vital choice look at here now for operators and managers alike.Integrating long lasting undercarriage components has actually shown substantial improvements in equipment efficiency. These instance studies underscore the tangible advantages of utilizing sturdy undercarriage components in maximizing equipment efficiency and long life.

In verdict, making use of sturdy undercarriage components can dramatically boost efficiency and long life of hefty machinery (undercarriage parts). Situation research studies have shown that spending in sturdy undercarriage components can lead to boosted general performance and productivity in various industries

Report this page